I received a Hornady LNL AP for my birthday. I have read a great deal about the care and feeding of these machines, and the trials and tribulations that some experienced. My press ran well for me after the initial setup, but there was one issue that bothered me. At index on the downstroke of the ram(handle moving up), the shellplate would jump the last few degrees as the balls went home into the detents. No amount of tuning with the pawls would cure the abnormal movement. Closer examination showed that the shell plate was riding slightly above the sub-plate until the balls started to ramp into the detents. As the balls tried to go home the shellplate would leap forward and then sit down onto the sub-plate. This was not so bad except for the fact that I was loading .40S&W and the flake powder would occasionally hop out of the cases. I went looking for a solution. I took the shellplate off and then removed the sub-plate, exposing the drive hub and drive shaft. Seeing the relationship of the parts showed that the height of the drive hub and the height of the sub-plate set the clearance for the shellplate against the sub-plate. I called Hornady CS and described my problem. They sent a new drive hub but it was identical to the one in the press.

What follows is my solution to this problem.

I started by measuring the height of the drive hub and the height of the sub-plate. I found that the drive hub was .014" taller than the sub-plate. This difference is what allowed the shellplate to float above the sub-plate during indexing. I am a machinist and I knew the issue could be solved on a milling machine, but I wanted to come up with a no-cut solution. The drive hub is 1" in diameter and the ram area that it sits in has a 1.562" bore. I began to search for a shim set that would work and found one without to much trouble or cost.

Now to the good part.

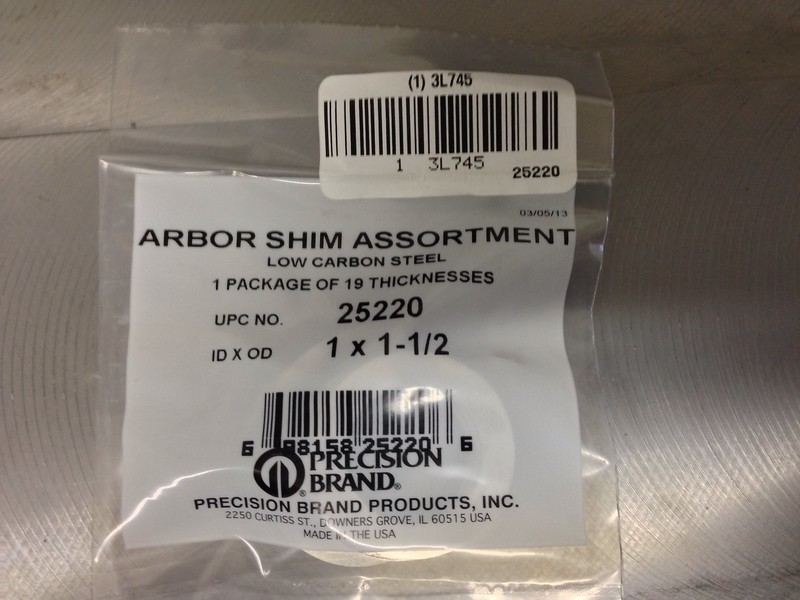

This is the shim assortment, with sizes from .001 to .125". 1"ID and 1.5"OD. $7.90 to my door from eBay.

Untitled by zweitakt250, on Flickr

Here you can see the drive hub sitting on the drive shaft.

Untitled by zweitakt250, on Flickr

Measuring the drive hub from shoulder to face shows that its critical dimension is .942"

Untitled by zweitakt250, on Flickr

Measuring the sub plate shows a height of .928"

Untitled by zweitakt250, on Flickr

This results in a .014" clearance. I knew it needed to be less. I decided to try a .004" clearance. Using the .01" shim showed great improvement, but I thought the clearance could go to .003". No .011" shim is provided so I made a stack out of a .005 and .006" shims.

Checking the stack.

Untitled by zweitakt250, on Flickr

The shims in place on the drive hub.

Untitled by zweitakt250, on Flickr

Now when the shell plate is tightened the drive hub will be pulled barely above flush, keeping the shellplate in contact with the sub-plate and making the indexing of the press ultra smooth.

Untitled by zweitakt250, on Flickr

If you read much at all about the AP you will find many that complain about the lack of ability to seat primers below flush. My first run of 100 rounds resulted in two high primers, the rest just flush. I determined that this was also a result of the shellplate rising from the sub-plate. Pushing harder on the handle only resulted in the primer punch housing bottoming against the frame. Now with the clearance set the press will seat primers below flush with ease.

I hope that this thread will help those with a Hornady AP to create better ammo and be able to enjoy their press even more. Thanks for looking!

Reply With Quote

Reply With Quote

Bookmarks