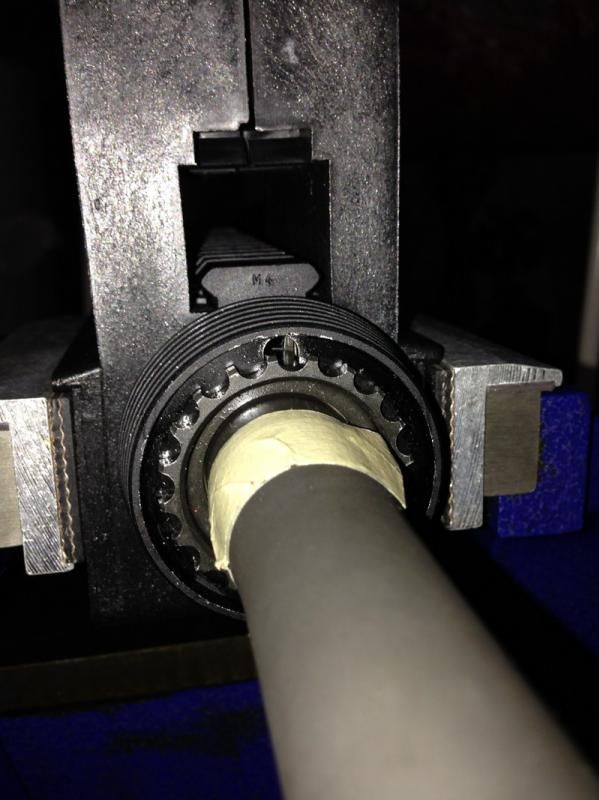

I just swapped out a 16.1" to 14.5" barrel.

Now, when I set the torque wrench to 30 ft-lb., it clicked and after checking, the gas tube aligned with the barrel nut and upper receiver.

Is this good enough? barrel secured with upper?

From other assembly vids I saw, after setting the wrench to 30, set it to 40 then go to next nut indentation. But in my case, I didn't have to go to 40 ft-lb.

I was just thinking that since my upper had a previous barrel installed before, I used a new nut with the 14.5" barrel. Then I torqued to 30, then loosen, then torque to 30 again and as far as I know I gave an extra torque maybe 1 ~ 2 ft-lb more when the wrench had clicked. But this time I just wanted to check the gas tube hole and it is aligned and was able to pass the tube smoothly.

Am I really good to go?

Reply With Quote

Reply With Quote

Bookmarks