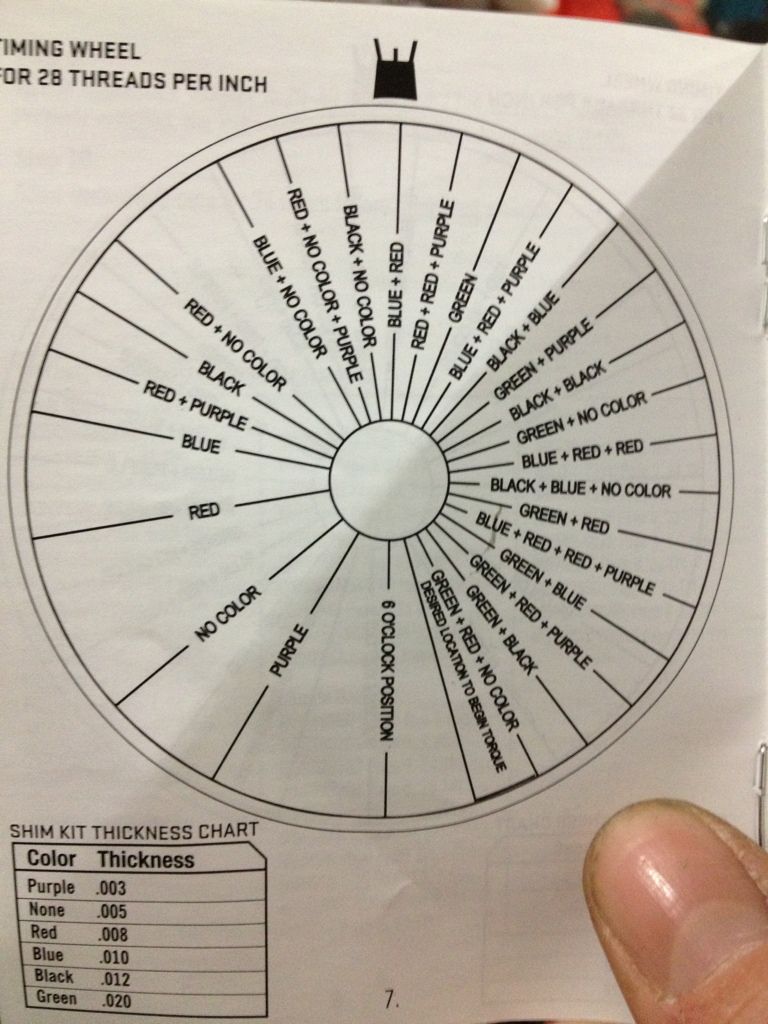

Installed my SF3P-556 on my MK18 tonight. I could not get the flash hider to time exactly straight up and down. I'm slightly OCD about things like this. I'm assuming this won't cause an issue. I tried the purple shim and it would only time with about 15 foot pounds. The next size up is the no-color shim and its with 30 foot pounds. This is whats on there now. I could probably get it to time with 35 foot pounds, but I dont believe that is recommended.

Reply With Quote

Reply With Quote

So probably to much. Maybe I should start over... is this going to be a PITA to get loose? How do you clean off rockset?

So probably to much. Maybe I should start over... is this going to be a PITA to get loose? How do you clean off rockset?

Bookmarks