|

||||||||||||||||||||||||||||||||||||||

Last edited by jmnielsen; 01-28-15 at 13:00.

Post number 5... Same diameter, but proper Grendel uses the original colt designed 7.62x39 bolt with a deeper cut. Some mfgs compromise and use 223 bolts opened up, which is weaker and Headspace's differently.

Although I'm now backfilling with lapua Grendel brass, for years I've used IMI 7.62x39 brass for Grendel. Very slight loss of case capacity due to thicker walls, but performs within 1-2% of factory Grendel.

This is one of the big wins for Grendel, never being stuck without a brass source relative to competitors like 6.8.

That and steel cased ammo availability made on 7.62x39 lines.

Pinzgauer is on the money here. There are several different bolt designs for the different calibers:

1) Original .222 Remington bolt, (made from 8620 and hard chromed) which set the geometry for the 5.56x45 bolts, but later needed upgrading to a tool steel. There are many different versions of the 5.56 bolts, even within model numbers from Colt, starting with the Colt 601 AR15 (green rifle). There were different band width dimensions, markings, and minor details on the early production chrome bolts.

2) Improved 5.56x45 bolts made from tool steel, which would later be known as Carpenter 158. There are variations in manufacturing methods, tool jig set-up for cutting the lugs, proofing, etc. This covers Colt RO603 (XM16E1 and M16A1) through M16A2 production. I'm still trying to determine whether 8620 with careful metallurgy was used on the 1960's-1970's production guns, but I think failures with the early 8620 bolts due to the significantly increased pressures resulted in tool steel being used early on. Most of the guys who would know are dead and gone. I remember operator manuals from the 1970's and 80's specifically mentioning PMCS'ing the bolts by checking for cracks, pitting, and requiring detailed inspection of the bolt. There were even pictures in the -10 booklets showing examples of bolt fatigue issues.

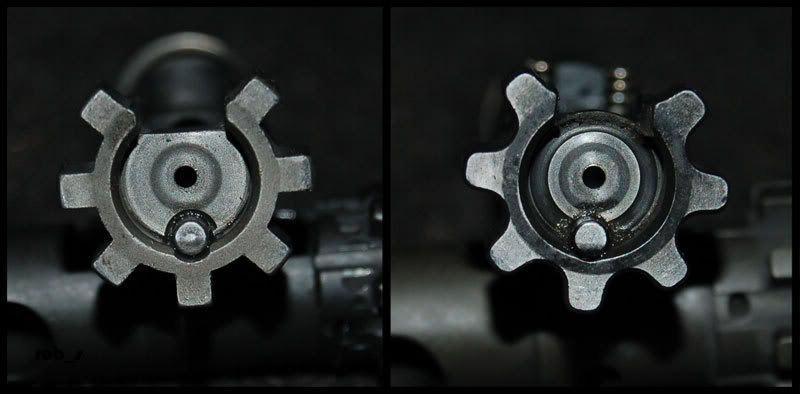

3) Colt 7.62x39 Sporter II bolts. When Colt's engineers looked at making the 7.62x39 work in the AR15, one of the first areas to address was the thicker .055-.057" case rim, and how it would feed in an AR15 bolt. This is where the idea for a .136" bolt face recess comes from, since you can't simply cut forward into your extractor lip to make room for the rim, and you now have constraints with extractor pivoting farther outwards due to the larger base diameter of the 7.62x39, which is .441"-.445". With the tight constraints of the 5.56x45 diameter barrel extension, you now have to look at extractor articulation more carefully as it snaps over the case rim, since the extractor can ride against the extension teeth, especially on a warped extension. Most of the institutional knowledge about the Colt 7.62x39 Sporter was lost when the guys who worked on it retired into obscurity.

4) AA .50 Beowulf/6.5 Grendel AR15 Bolt. This bolt was heavily influenced by the RDT&E that Colt had done for the 7.62x39, and there are several important differences. This bolt then became the 6.5 Grendel bolt years later. The current bolts use a .136" depth, longer overall length of 2.810" so normal firing pins can be used without need for a special short pin, and .278" long lugs. The AA bolts undergo destructive testing in batches, to ensure that the metallurgy is right, which is why we don't see broken bolts with them unless something is wrong with the load or alignment of the barrel extension to the upper, which will break any bolt. AA still has an original bolt in a full-auto testing apparatus that has yet to break after all these years, so they are one of the most well-engineered, highly QC'd bolts on the market.

5) 6.8 SPC bolt. Since the 6.8 SPC uses a .049" rim thickness, it isn't that much more than a 5.56's .045" rim, so the .124" bolt face depth works out fine.

No matter what caliber is being stuffed into the AR15, since all of the ones we shoot through it were never within the design considerations when Jim Sullivan and Robert Freemont drafted up the 1957 AR15 schematics, metallurgy of the bolt is much more critical than on an AR10, for example, where 8620 and the sheer mass of the bolt body and lugs are more than sufficient to handle .308 pressures.

The tiny features of the AR15 bolt lugs, and narrow bolt body, combined with the cam pin hole were fine for the .222 Remington's 50,000psi maximum SAAMI working pressure, but really lacking when it comes to the full-powered 5.56x45 NATO, when working pressures jumped up to 58,000psi, and now 62,000psi, hence the C-158 bolts, HPT, shot peening, and MPI testing.

The SCAR-16 has about the ideal bolt body and lug size for a 5.56x45 NATO weapon. KAC addressed this with their E3 bolts, using stronger radiused lug root arrangement and interface with the barrel extension, reminiscent of the Professional Ordnance Carbon 15 guns.

SCAR-16 next to standard AR15

KAC E3

Last edited by LRRPF52; 01-30-15 at 14:07.

Bookmarks