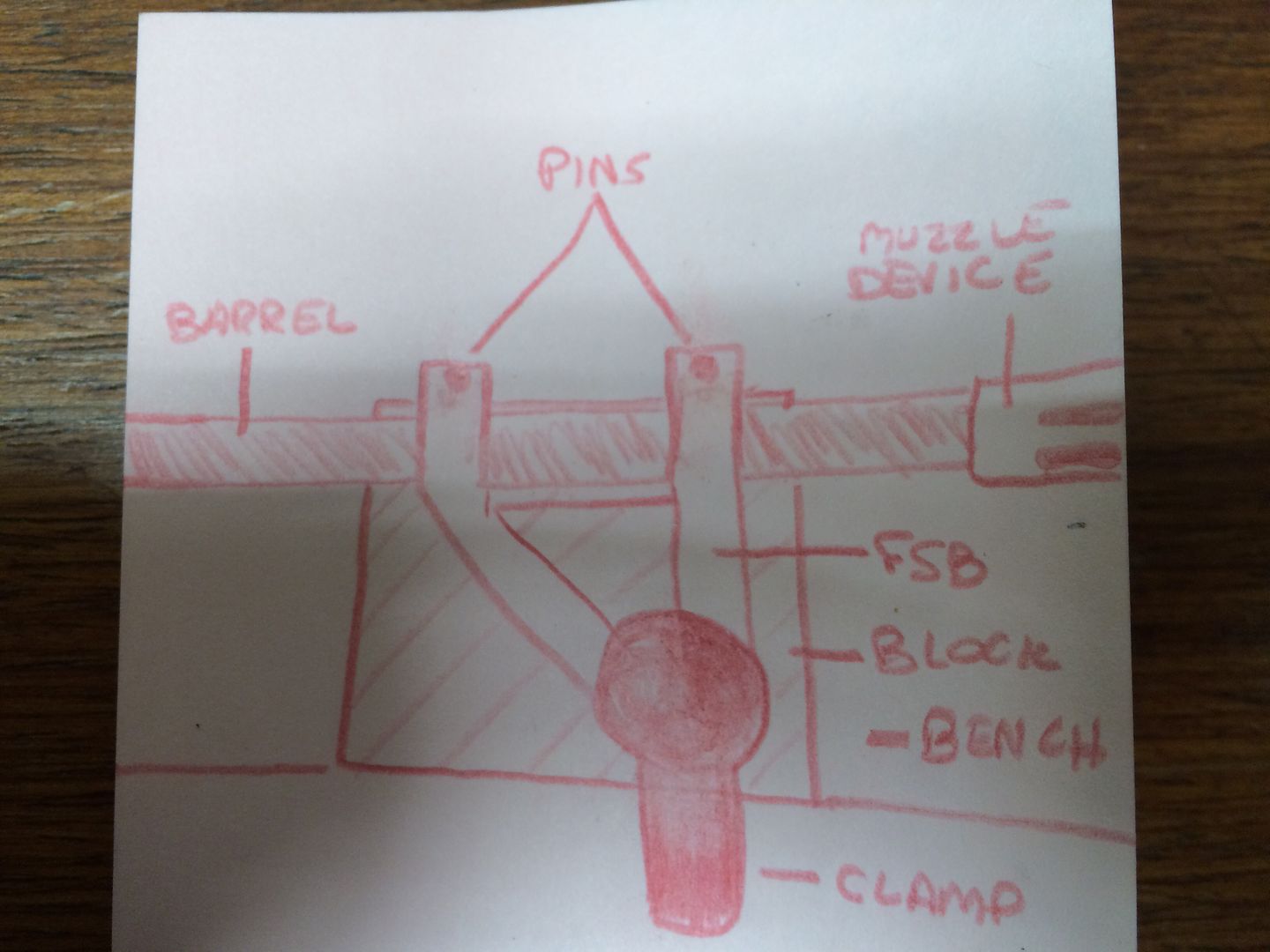

I removed, shaved, and reinstalled the FSB from a S&W M&P15 earlier this year. It had approximately 3000 rounds through it at that point. The pins weren't super easy, but using a punch that has a concave tip made it doable. In my case, the pins were backwards to what I read BCM is, and were also backwards according to the Brownells FSB Armorer Block. Having a buddy help hold the upper was a big plus.

Since I had it off, I installed a Black River Tactical Custom Tune Gas Port to address the barrel being overgassed. It wasn't requirement, but sure did make an appreciable difference.

Reply With Quote

Reply With Quote

Bookmarks