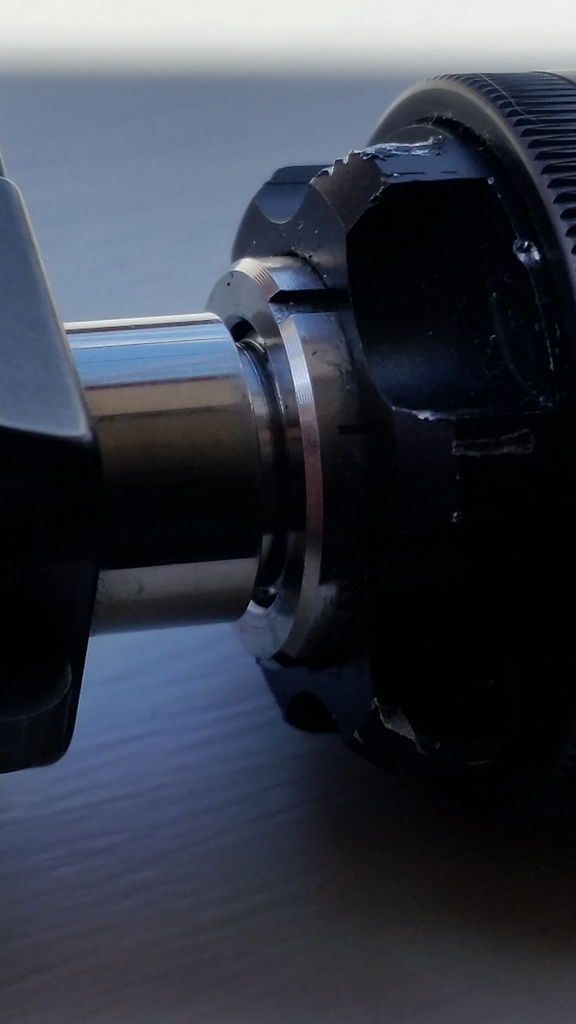

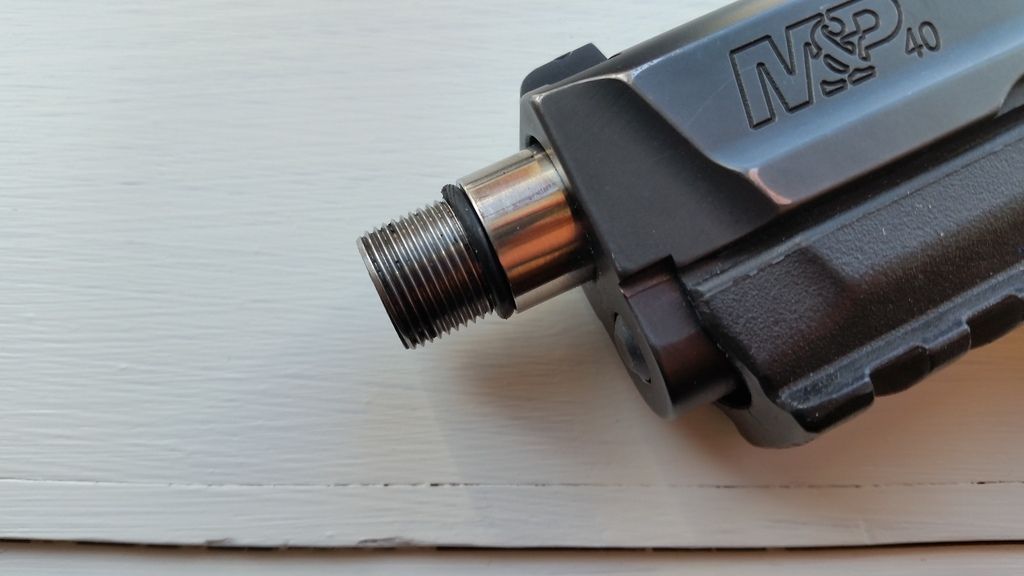

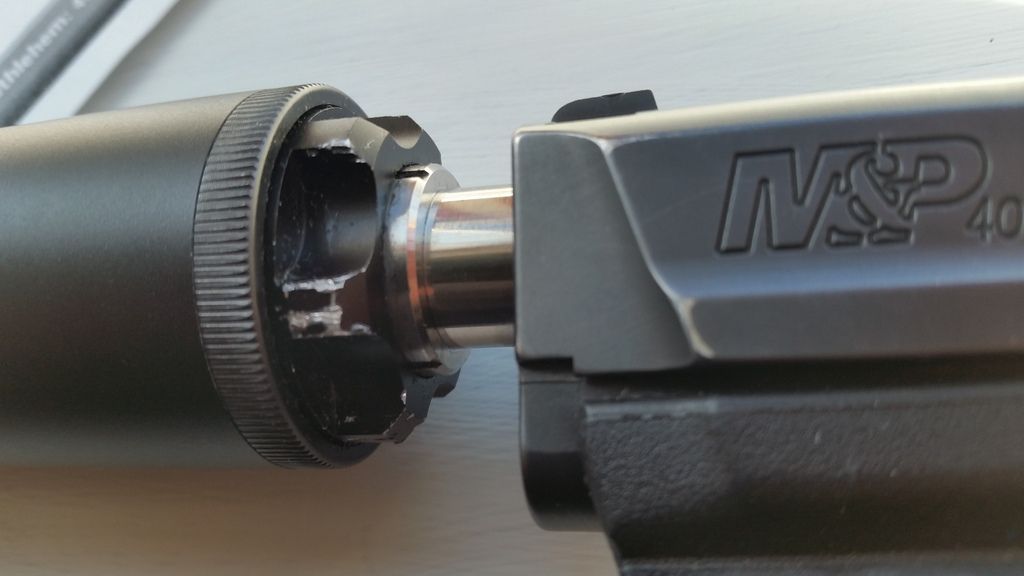

Man, I have a bear of a time removing my booster &/or the piston retainer after shooting. When I read in the manual that they recommend thread locker, I thought they're insane. I even started oiling the threads when I reassemble the can after cleaning. That seems to help but just barely. The can stays put on the barrel too.

I wonder why such a difference.

Reply With Quote

Reply With Quote

Bookmarks