I posted a while back about the A2 build I completed and asked some questions about FSB alignment and install etc.....

The 20" Colt barrel didn't come with an FSB installed.

- I didn't want to PIN the FSB as I don't have the necessary equipment and I don't want to drill a barrel.

- I don't want to go to the hassle of shipping it somewhere and have someone pin it as I don't trust anyone to do it correctly.

Given all of this and that Colt FSB's were hard to find, I decided to go with a JP Clamp on, which went on smoothly.

I was never really satisfied with the JP clamp on FSB for a couple of reasons.

- It was adjustable and I don't want an adjustable gas block on this rifle

- It didn't look right with most all of the other parts being Colt OEM

I was finally able to source some FSB's and purchased a few with the intention of using one of them on this rifle.

I looked at options for installation and this is how I decided to install.

Tools required to modify the FSB: #21 Drill - 10-32 Tap

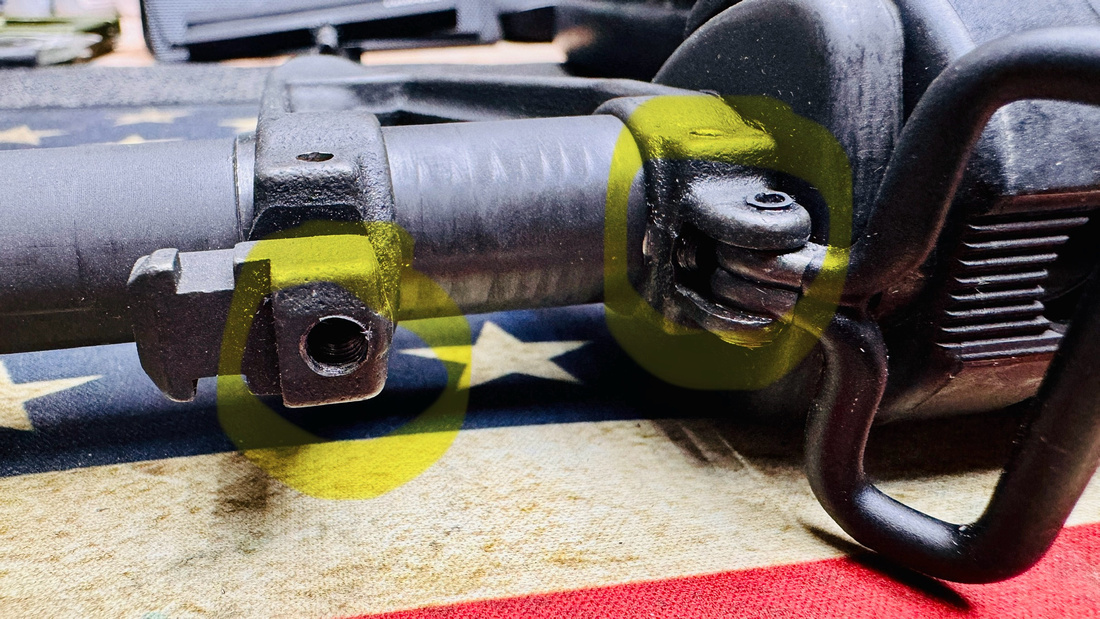

I drilled, a #21 Bit, hole through the FSB, then tapped it with a 10-32 tap which is the correct size for Low Profile gas block set screws.

It came out really nice and seems very secure, only time will tell how this works out and yes, I realize it isn't nearly as secure as pinning.

The picture below illustrates the final product. One hole you can see, (Pretty Deep) the second hole is under the sling swivel which I removed and re-installed.

This won't be for everyone, obviously. But hopefully it helps someone out with an option in the future. I am not a machinist, so if I can do it, nearly anyone can.

Reply With Quote

Reply With Quote

Bookmarks