Well, If you reload enough, its bound to happen. You will not properly lube a rifle case and it will become stuck in your sizing die. Its not if, but when. So here is a how to, on the best way to remove the stuck brass. This is fairly simple and only takes about 5 minutes.

Put the vise-grips and pliers up before you ruin the sizing die. You are not going to be able to pull the bass out of the die like that. Also put up the punch. The punch maybe faster, but its a good way to damage the threads inside the die.

Here is a list of tools that you will need. I suggest you purchase the tap, T-handled tap wrench, and bolt before you have a stuck case. The rest of the tools are common and you should have them on hand.

1. crescent wrench

2. needle nose pliers

3. Drill

4. #7 drill bit

5. 1/4 x 20 tpi tap tapered

6. T-handle tap wrench

7. primer pocket Swagger base that removes primer pocket crimp (3/4" socket will work if you do not have a swaggger base)

8.1/4"x20 TPI x 1" bolt (Allen or regular bolt head)

9. Allen wrench or socket to fit the 1" bolt

10. Oil for the tap

Swagger base

Okay, now onto the How To;

Stuck Case. Notice the rim is pulled through the shell holder.

Now remove the decapping pin.

I use pliers to loosen it and then pull it out of the case mouth.

Since the decapping pin is removed, use the crescent wrench and remove the sizing die from the press.

Now install the die upside down. You will need to tighten the die up so the die will not twist loose when you use the drill.

Drill the primer pocket with the 1/4 drill bit. Do NOT add oil/lube at this time because it can cause the case to spin inside the die, thus preventing you from drilling out the primer pocket.

Next add some oil between the case and die.

Now use the T-handle wrench and the 1/4" x 20 tpi and thread the inside of the case where you drilled out the primer pocket. Use a tapered Tap because it will be easier to start and use the 20 tpi not the 28 tpi since it is harder to strip out the threads on the 20 tpi when trying to remove the case. Use caution not to break off the tap inside the brass case. Go back and forth when using the tap by loosing and tightening the tap. This will help the tap cut the threads easier.

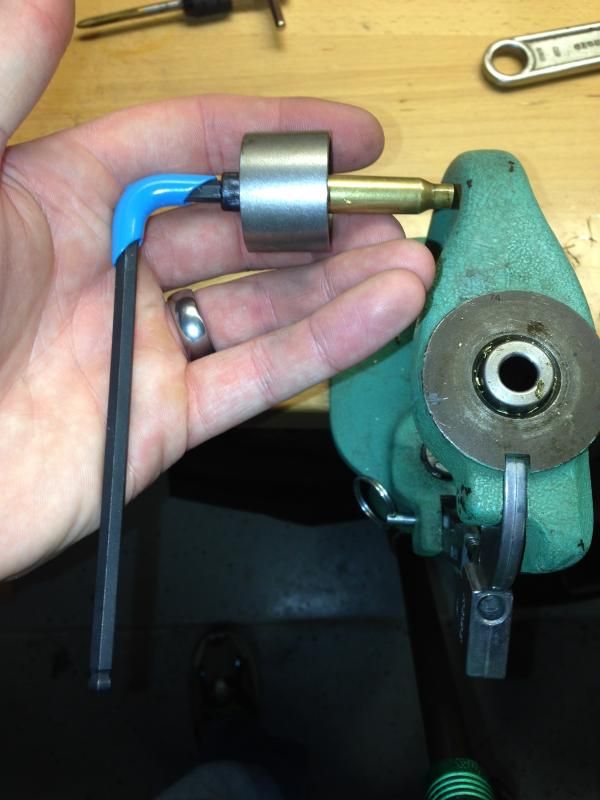

Once you have the case threaded, then place the swagger base on top of the case and run the bolt through the top and thread it into the brass case.

If you do not have a swagger base, Here's a pic of the socket . It works the same way.

Now just tighten the bolt where it pulls out the stuck case.

Be sure to clean out the brass chips from sizing die and properly lube all your bass cases from here on out. I know this is a long review with lots of pictures, but I want it to be through. Hopefully this will help someone out in the future.

Reply With Quote

Reply With Quote

Bookmarks