Originally Posted by

WillBrink

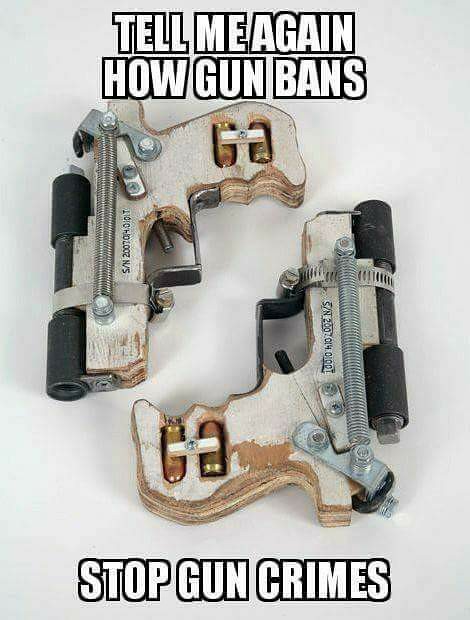

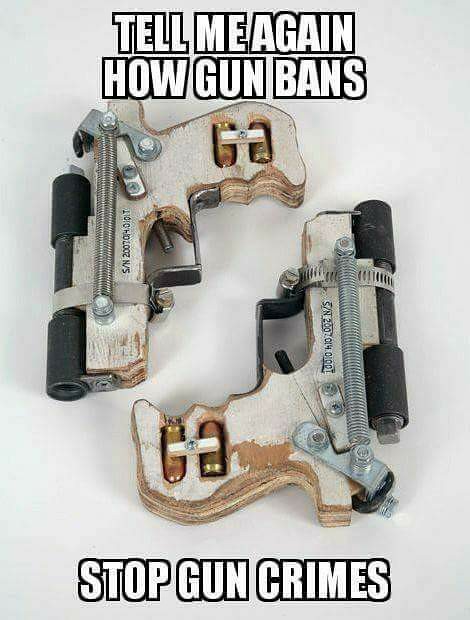

It just shows us with modern tech, gun control will only impact those who follow laws. No doubt, a push for a ban is in the works:

Just wait for these idiots to find out you can make a Sten from odds and ends picked up at your local Ace Hardware.

"In a nut shell, if it ever goes to Civil War, I'm afraid I'll be in the middle 70%, shooting at both sides" — 26 Inf

"We have to stop demonizing people and realize the biggest terror threat in this country is white men, most of them radicalized to the right, and we have to start doing something about them." — CNN's Don Lemon 10/30/18

Reply With Quote

Reply With Quote

Bookmarks