LORDS OF METAL

We are starting off this review a little different. I just got done talking back and forth with the manufacturer, and asked for a high carbon steel blade as opposed to overseas D2 that typically comes on the knife. Why? My main reason is that overseas D2 is often not the same as what we think of as D2 here in the states. More than that, often it is just a name for a lower grade of steel that isn't even close to real D2. I'll point out that this manufacturer is one I have never dealt with, and I have no reason to think they are out to make a bad deal with me, but High Carbon blades are easier to sharpen and even without the gained abilities of D2, its easier for me to test. Yes, when the blades get here, I will spark test them to get a rough idea of what the carbon content is. While I might not be able to make the most accurate reading, I'll be able to come pretty close.

The knives we are looking at are similar to the ones made famous by Randall Knives. At least similar to the basic layout and look. One will be with finger grooves and one without. My nephew will get the one with finger grooves, and I'll use the other. Two knives should be able to give us a pretty good idea of how well they do.

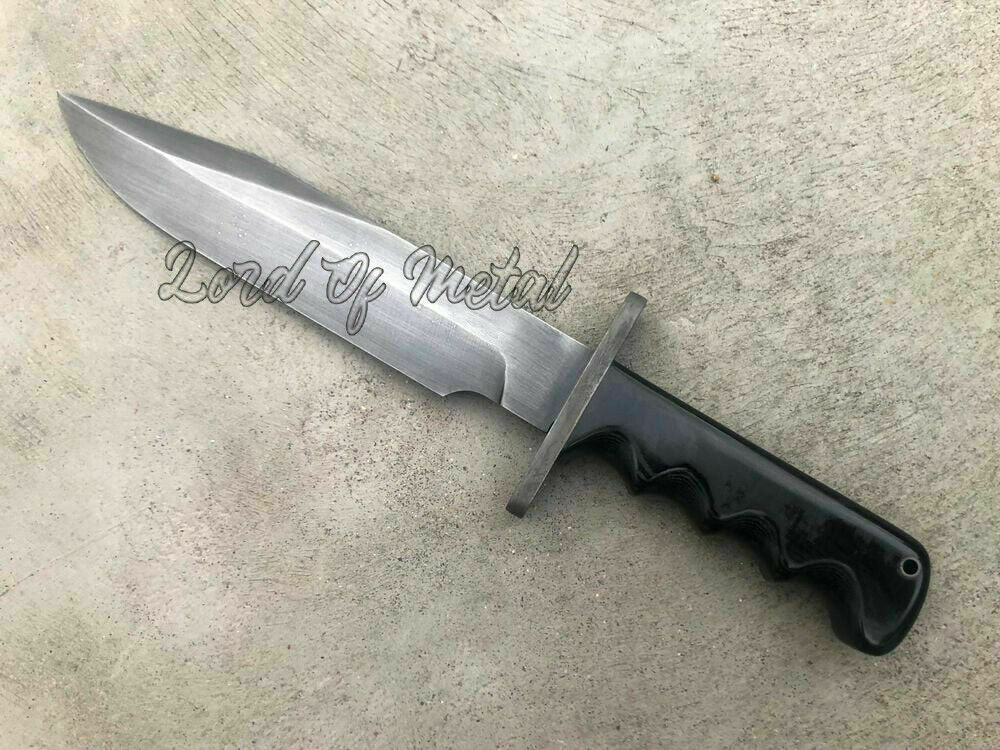

This is one of the pictures from Lord Of Metal showing what one should look like. They should be coming with leather sheaths, which are stated to be thick leather, and not the thin stuff that rips easy. The grips are stated to be made of Micarta.

The below picture is one of mine, you can see that this one (Black Jack not a Randall) is pretty similar, so I have a good idea of how it should handle and feel.

I'll post updates so people can get an idea of how long the process is, as well as post a lot of images once the knives are received. We will test the steel via spark testing, as well as lots of real world testing to see how they hold up. If they are great, we will let you know. If we wasted our money, we will certainly let you know that as well. Obviously I'm hoping things turn out well, and if they do, we will look at other knives and review them as well.

When Lord Of Metal (LOM) found out I was writing an article, they asked me to point out others have copied use of their name. I don't mean hot blondes on leather singing death metal on tour ( I still love you Dora Pesch). My point of contact is named Faisal Mughal. Once the blades show up, and I can get at least a partial review, I'll post links along with my thoughts and images.

*** update 12/28/21 ***

The knives are in and I've been playing around with them for a few weeks. Lets start with the below knife first:

Initial impressions were based on the sheath, so lets start there. The sheath in my humble opinion is one of the most overlooked parts of a knife, but if your sheath isn't secure, your knife ends up on the ground lost in the woods. If it is overly secure and hard to put in, your sheath will dull your blade (like the Cold Steel plastic sheaths were notorious for). A tight sheath is also horrible to retrieve a blade from, especially when you are doing it in a hurry one handed.

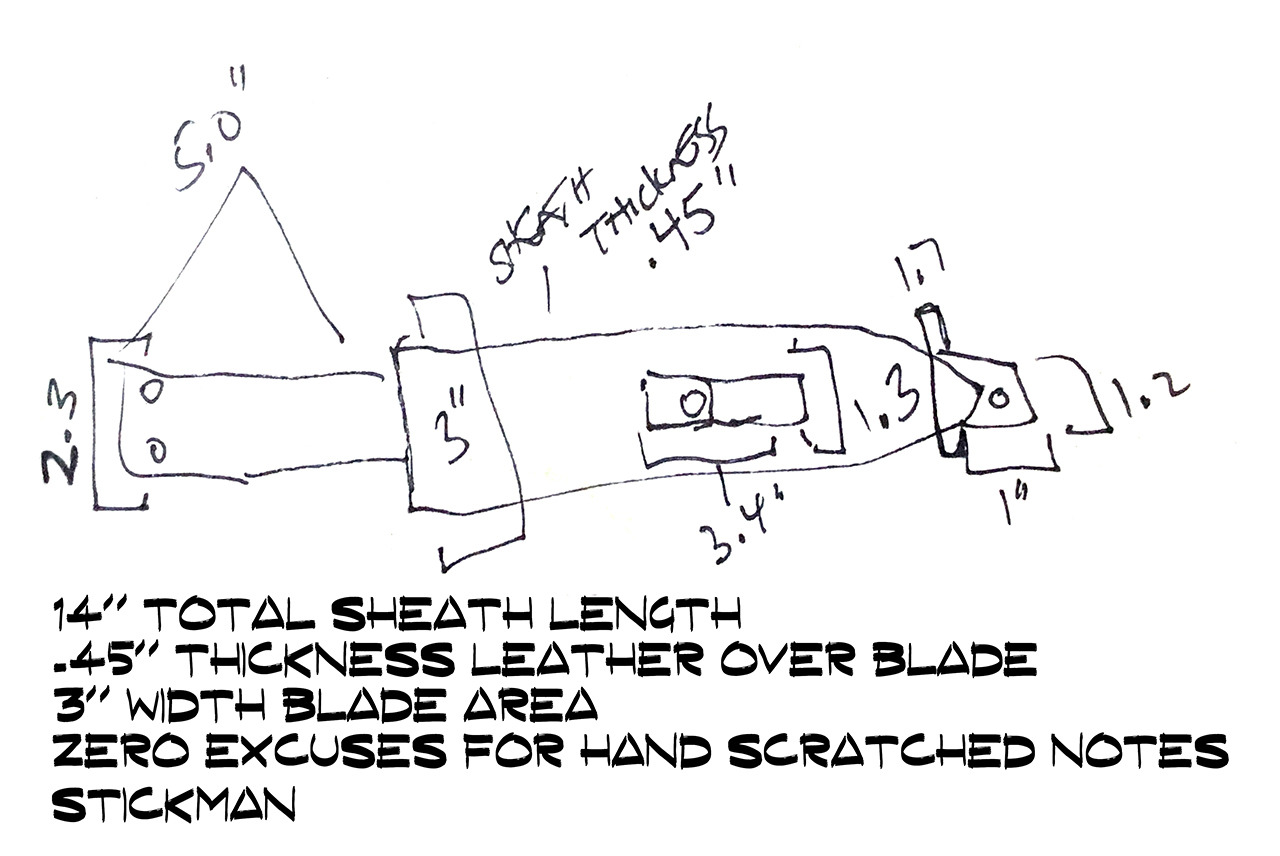

When you are done laughing at my quick sketch shown below (I'm laughing as well), you can see measurements for the sheath in most areas. I'll translate the highlights. The overall length of the sheath is 14", which seems about right when you figure in the leg tie down. Since we are looking at a roughly 12" knife, the additional leather sticking out over each end lends itself to tie downs, mounting methods, and a little extra end spacing inside the sheath. The overall width of the sheath is 3" in the blade area, and 2.3" above the guard.

The center of the sheath has a leather pouch sewn in, of the type typically used for carrying a sharpening stone, or as many people do, a small fishing kit, 550 cord or other small items can be retained inside. The pouch is 3.4" in length, and 1.3" in width.

Speaking of cordage, the OD Green cord which wraps the sheath is not nylon 550 cord. I read a review where a buyer was horribly offended by this, however, on this sheath I can find zero complaints. There is nothing wrong with cotton cord, it chars instead of melting. The flipside is that it doesn't carry the weight of 550 cord, and you can't gut the cord quite the same to pull "fishing line" out. If you want 550 cord you will need to install it yourself. I consider that an individual issue, and not a realistic complaint. Wrap the sheath in duct tape if you want, wrap it in 50 cord if you want, or leave it with cotton cord. Your own individual needs are what should be considered. I find the insertion if any cordage at all to be a good thing.

Let us talk about the leather before we get to the part about stitching. The brown leather used on all three sheaths I ordered (2 blades & one extra sheath) are exceedingly attractive to my eye. The leather measures out to .45" in thickness with three pieces together on the blade section. If we do the math, that means we are looking at roughly 9.5 ounce leather. Consulting Dr. Google for knowledge, we find ( https://montanaleather.com/leather-t...version-chart/ ) this thickness suitable for heavy holsters, heavy belts, or light armor. I'm not saying to use your sheath as armor, but I do think it points out this is not the same cheap thin leather used on many imported knife sheaths. The more I think about it, it is a thicker, nicer cut of leather than most of the aftermarket sheaths I have purchased which claim they are made in the states. The leather is not dry or hard, and has been treated by something, but I have no idea what. All of my own leather is treated with Ballistol, so that is what I soaked this one with as well. The Ballistol soaked several coats in, and added a nice smell to the room.

Stitching is a topic worth discussing on its own. These sheaths use what appears to be nylon thread, and of the heavy duty type. I am not skilled by eye or trade in the way of the sewing machine, but that does not stop me from appreciating the heavy thread used. Much in the same manner, I also appreciate the reinforcements at the starting and stopping points, which are usually the areas that are going to see the most abuse, by way of leveraging the knife as it is pulled out cockeyed or if it is caught on something. The reinforcements are double stitched on the top, and triple stitched where the knife comes out of the sheath. These are small points which show fine attention to details that really matter.

The opening area for mounting the sheath to a belt measures out to a belt width of 3.5". If you have a belt wider than 3.5", you would need to bend your belt to get it through, find a smaller belt, or have modifications made. For the vast majority of us, this will be more than adequate with the exception of a padded war belt. If you are putting this on a padded war belt, you will probably need to get crafty with zip ties, tape, or whatever else you have in your garage. When you consider a wide belt is 2", this can not give serious umbrage to anyone.

The last part I think we can delve into is the snaps. There are two snaps present. One for the retention of the blade, and one for retention of the small pocket on the front of the sheath. The snaps measured .525" on the female section, and .39" on the male protrusion. The snaps appear heavy duty and securely fastened. They also appear to be chrome plated, which is a plus for inclement weather.

In short, all three of these sheaths show exceptional quality. They fit the blade well, and come ready for use.

Reply With Quote

Reply With Quote

Bookmarks